Production Technology

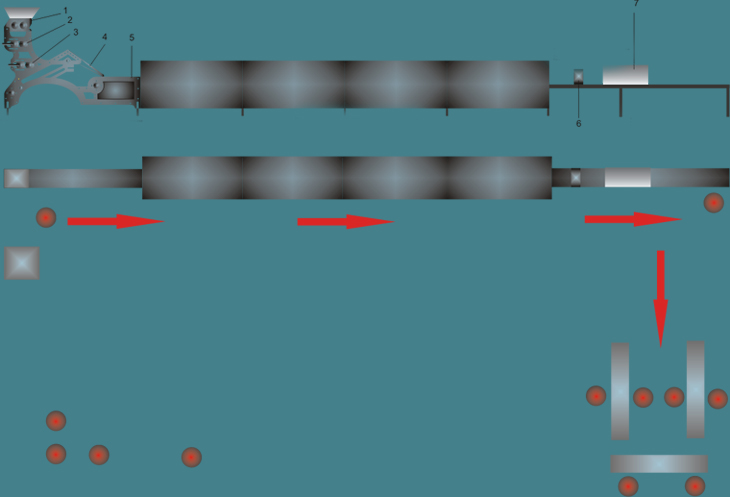

1. The ready dough is put into the moulding matrix feeder (Fig. 1). The moulding matrix feeds a dough layer of a certain thickness and width by infusion method. The dough thickness and width depend on the internal mounding pressure. The internal pressure is regulated by the variable speed drive, which increases and reduces the rotary speed of the feed shaft motor.

.JPG)

Fig. 1

2. After the matrix, the dough of certain form gets through the first rolling pair of the dough roller, which rolls the dough out from 4 mm to a 1.3 mm thick layer (Fig. 2). The first rolling pair is also regulated simultaneously with the matrix feeding by the variable speed drive, which regulates the motor speed of the first rolling pair.

Fig. 2

3. After the first rolling pair, the 1.3 mm thick layer proceeds to the second rolling pair of the dough roller. After the second rolling pair, the dough layer achieves a thickness of 0.5 mm (Fig. 3). The second rolling pair rotary speed is simultaneous with that of the first one; it is also regulated by the variable speed drive.

Fig. 3

4. A 0.5 mm layer moves from the second rolling pair to the stretching conveyor belt where it is stretched to a 0.2 mm thick layer. The stretching conveyor transfers the dough layer to the tunnel oven crawler track (Fig. 4). The stretching conveyor belt speed is associated with the tunnel oven crawler speed and is regulated by the same variable speed drive.

Fig. 4

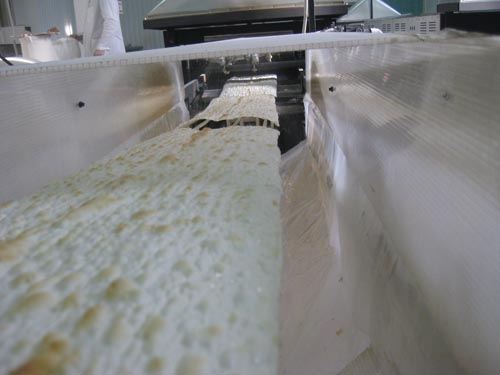

5. The tunnel oven with a 6 m long crawler track and a temperature mode of 380-400 degrees bakes a 0.2 mm thick dough layer within 50 sec until it is finished.

.jpg)

Fig. 5

6. After baking in the oven, a dry lavash sheet is cut with a rotary guillotine knife (Fig. 5). The lavash sheet length depends on the guillotine knife rotary speed, which is regulated by the variable speed drive.

7. After cutting the lavash into pieces of certain length, it moves to the moistening conveyor belt (Fig. 6). The moistening conveyor belt consists of four polyurethane rotating cords 8 mm thick and 3000 mm long.

Fig. 6

The finished lavash goes under the water sprayers and receives enough moisture for achieving the necessary degree of lavash softness. After moistening, the finished lavash is transferred to the packaging area.

8. Wheat rolls (Armenian lavash) production line characteristics:

- Length: 11 m

- Width: 60 cm

- Height: 130 cm

- Productivity: 600 pieces of lavash each of weight 200 g, length 1200 mm, width 330 mm.

Two workers are required for the line operation:

1. Dough-maker

2. Finished products receiver